Today’s Rubber Technology

Rubber Technology & Applications

Natural rubber has been around for as long as there have been rubber trees on the Earth—quite a long time, as you might imagine.

Early indigenous Mesoamerican cultures produced stabilized rubber for containers, waterproofing, and recreational balls as early as 1600 BC.

The first scientific paper about rubber was presented in 1751 by the man who would create rubber erasers as we know them today. Charles Goodyear developed modern practices of vulcanization in 1839.

Since then, plastics engineering and rubber technology has come a long way. You can find it everywhere—from erasers to textiles, carpeting to adhesives. Rubber innovations have created a whole new arena of possibilities for rubber.

Rubber Innovations at ACE

At ACE Laboratories, we drive innovation, test limits, and meet challenges head on to help you create products that shape the future.

Contact us to discuss what we can do for you.

Below, learn more about the rubber technology we use every day to help our clients achieve new levels of success.

Rubber Vulcanization

Today, almost every rubber product you see is vulcanized.

During vulcanization, small amounts of sulphur or another cross-linking agent are heated with rubber so the polymer chains become stabilized. Vulcanization can only occur with double bonded polymer chains, like natural rubber and polybutadiene.

Once rubber has been vulcanized, it is stronger, more heat resistant, and more elastic.

At ACE, we can test various vulcanization properties to ensure your rubber product is performing at or above its desired level.

For example, our ODR and MDR tests determine the vulcanization properties of compounded rubber materials. Testing these characteristics helps you meet quality control standards, as well as supporting research and development for your product.

Compound Analysis

During compound analysis, a material is examined for the presence of, and sometimes the quantity of, elements and compounds. Isotopic composition can also be studied during this process.

One testing option for compound analysis is ACE’s FTIR (Fourier Transform Infrared) machine. This test determines the polymer type present in a compound.

Since material properties like elasticity can change during vulcanization and other processing steps, knowledge of your compound’s polymer type is an essential step. This information can inform end use applications and competitive benchmarking.

Polymerization

Rubber polymers are formed through polymerization, when similar or varied monomers chemically combine to form a large chain or network molecule.

The process is different from other processes in which molecules form, like crystallization, because polymerization requires the formation of stable covalent chemical bonds between monomers.

Typically, these larger molecules—the polymers—must be made of at least one hundred monomers before they acquire unique attributes, like elasticity or high tensile strength.

Rubber technology relies on the creation of polymers—after all, rubber is known for its bouncy elasticity and strength.

Testing these qualities in a certified, trustworthy lab assures your distributors and your end consumers that your rubber product is up to par with industry standards, and performs as promised.

To test for elasticity, ACE performs tear resistance testing to predict the point where a material sample will tear or tensile / elongation testing to determine how far the material can stretch. For accurate results, it is important that the tests are directly related to the intended end use of the product.

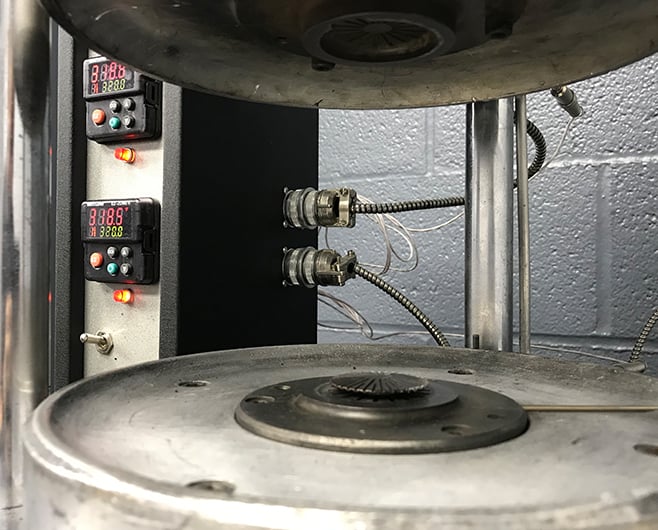

Dynamic Mechanical Analysis

Dynamic mechanical analysis (DMA) is most often used to study the viscoelastic properties and behavior of polymers. Polymers that are made of long molecule chains have unique viscoelastic properties—a combination of the characteristics of elastic solids and Newtonian fluids.

During analysis, ACE exposes the material to be tested to sinusoidal stress. We then measure the strain in the material to determine the complex modulus.

We can vary the temperature of the material to produce variations in the complex modulus for a more thorough look at your material’s behavior. Changes in a polymer’s composition and cross-linking can also vary the results from DMA testing.

At ACE, our DMA machine has high end capabilities for precise and accurate results about your rubber material.

The Preparation of Silicones

Silicones are some of the most useful polymers for weatherproofing and waterproofing. They are often used to make waterproof papers, wood, wool, and other textiles. They can also be incorporated into paint to create waterproof paints for outdoor applications, like porches and exterior walls.

Silicone technology also brings us antifoaming agents in industrial processes, mold releasing agents, silicone adhesives, and electrical condensers.

Make Today’s Rubber Technology Work for You

Rubber technology is advancing every day. ACE is here to take on your polymer testing challenges to make your rubber materials as effective and innovative as possible. To learn about Ace’s other laboratory expansions read about the CubeOne Robot

In the news

What Is FDA CFR 21 177.2600 and How Can I be Compliant?

The consumer goods industry is highly regulated, especially regarding food safety. If you’re making any kind of rubber or polymer part for machines that process food, you need to understand and comply with the FDA’s 21 CFR 177.2600 regulations. This standard is often...

What is Crack Bridging?

Crack bridging is the flexible substance that seals cracks in concrete, asphalt and other substrates. It may also be referred to as crack or joint sealant. Both cold- and hot-applied crack bridging materials are commonly used. Asphalt plug joints are a type of crack...